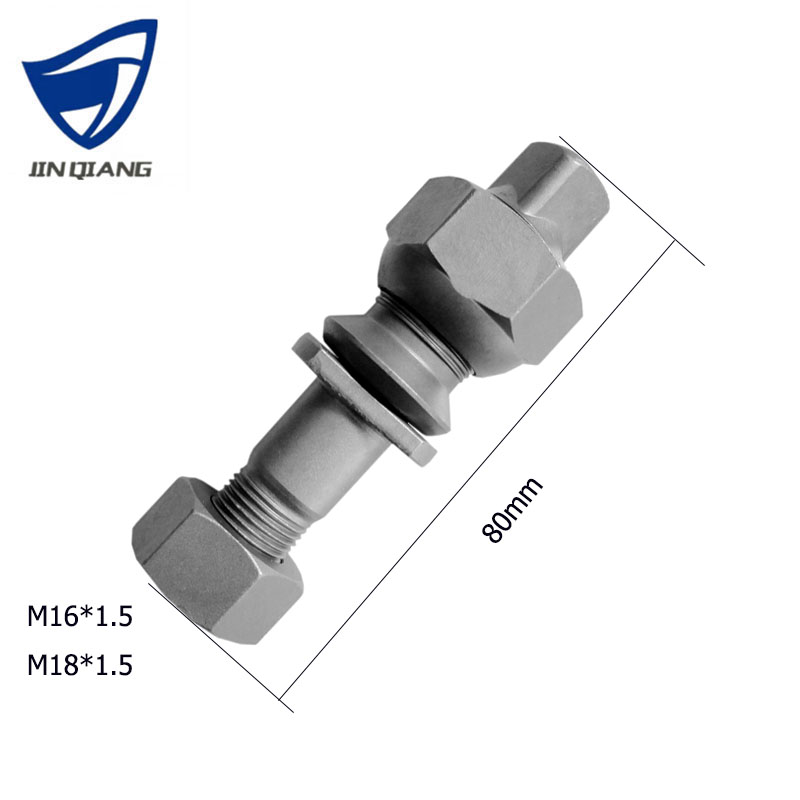

Hot sale Wheel Chock Bracket - Leaf Spring Casting Pin Bracket – JINQIANG Detail:

Advantages of company

1. Professional level

Selected materials, in strict accordance with industry standards, production contract satisfactory products, to ensure product strength and accuracy!

2. Exquisite craftsmanship

The surface is smooth, the screw teeth are deep, the force is even, the connection is firm, and the rotation will not slip!

3. Quality control

ISO9001 certified manufacturer, quality assurance, advanced testing equipment, strict testing of products, guarantee product standards, controllable throughout the process!

4. Non-standard customization

Professionals, factory customization, factory direct sales, non-standard customization, customized drawings can be customized, and the delivery time is controllable!

description

Casting of metal products consists of a series of intricate manufacturing processes that need to be precisely conducted and controlled. Rather than doing process design by a hit-and-trial approach, simulations can be run before casting is actually undertaken in a foundry. These simulations allow to model, verify, and validate the entire casting process along with the prediction of possible defects in the cast products. This study is based on casting an adjuster bracket using traditional mold design approach, and also using simulation. A Computer-Aided Design (CAD) model of the casting is developed in SOLIDWORKS and simulated using MAGMASoft. The results obtained are temperature profile within the mold after pouring, solidification sequence, and casting defects such as porosity and hotspots. Good correlation between experimental and simulation results confirmed sufficient model health to virtually optimize the mold through simulations. The optimized mold design completely removed the hotspot and reduced porosity which is within the machining allowance of the final product. However, the casting yield is reduced by 6% by adding a carefully selected riser in the optimized mold design. It can be concluded that simulations are reasonably accurate in modeling casting process, predicting defects, and modifying casting design using optimization techniques available in the advanced casting simulation software.

Product detail pictures:

Related Product Guide:

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most competitive prices. So Profi Tools offer you best value of money and we are ready to develop together with Hot sale Wheel Chock Bracket - Leaf Spring Casting Pin Bracket – JINQIANG , The product will supply to all over the world, such as: Paraguay, Poland, Sacramento, Since its foundation , the company keeps living up to the belief of honest selling , best quality , people-orientation and benefits to customers. We are doing everything to offer our customers with best services and best products . We promise that we'll be responsible all the way to the end once our services begin.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.