A Comprehensive Guide from Appearance to Performance – Avoid Quality Pitfalls in Procurement

In fields such as mechanical equipment, construction engineering, and automotive manufacturing, the quality of bolts is directly related to the safety and reliability of the overall structure. As a bolt manufacturer with 20 years of professional experience, our factory has summarized five core quality judgment standards to help customers quickly identify high-quality bolts and reduce procurement risks.

一、Visual Inspection: The First Line of Defense.

1.Surface Treatment

- High-quality bolts: Even coating without bubbles, consistent color (e.g., silver-white for zinc-plated, matte gray for Dacromet).

- Low-quality signs:Rust spots, uncoated areas, or obvious color differences.

2. Thread Precision

- Qualified standard: Clear thread profile, no burrs or deformations, 100% pass rate in Go/No-Go gauge tests.

- Pro Tip:Gently scratch the threads with a fingernail—poor-quality bolts may deform or shed metal flakes.

二、Dimensional Accuracy: Digital Measurement Assurance

- Key parameters:Head width, thread pitch diameter, shank straightness.

- Testing tools:

- Routine inspection: Digital calipers (accuracy: 0.01mm).

- High-precision requirements: Optical comparators (error ≤ 0.005mm).

Case Study: A client faced assembly failures due to a 0.1mm deviation in bolt head thickness—resolved after adopting our full-inspection process.

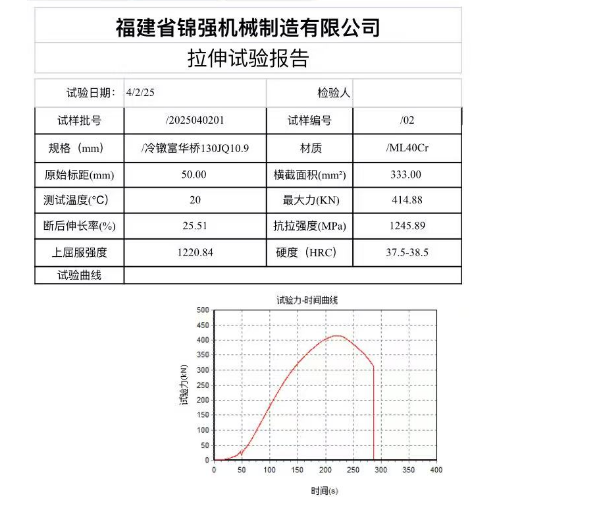

三、 Mechanical Properties: Lab-Grade Testing

| Test Item | Standard (Grade 10.9 Example) | Common Failure Risks |

| Tensile Strength | ≥800MPa | Bolt fracture |

| Yield Strength | ≥640MPa | Thread stripping |

| Hardness | HRC 22-32 | Brittle cracking or deformation |

Note: We provide third-party test reports (including tensile stress-strain curves) for every batch.

四、Special Environmental Resistance

- Salt Spray Test

- Standard zinc plating: ≥72 hours without red rust.

- Dacromet coating: ≥500 hours without white rust.

2. Hydrogen Embrittlement (High-Strength Bolts)

- - Delayed fracture test (200-hour load endurance).

五、 Certifications & Traceability: Invisible Quality Assuranc

- Certifications:ISO 9001, IATF 16949 (automotive), EN 15048 (structural steel).

- Traceability:Laser-marked batch numbers for full lifecycle tracking.

Post time: Jun-06-2025