The slack adjuster, particularly the automatic slack adjuster (ASA), is a critical safety component in the drum brake systems of commercial vehicles (like trucks, buses, and trailers). Its function is far more complex than that of a simple connecting rod.

1. What Exactly Is It?

In simple terms, the slack adjuster is the “bridge” and the “smart regulator” between the brake chamber (commonly known as the “air can” or “brake pot”) and the S-camshaft (or brake camshaft).

The Bridge Function:** When you press the brake pedal, the brake chamber pushes out a pushrod. This pushrod acts on the slack adjuster, which in turn rotates the S-camshaft. The camshaft then spreads the brake shoes apart, forcing the linings against the brake drum to create friction and stopping power.

The Regulator Function:This is its more critical role. It automatically compensates for the increased clearance caused by brake lining wear, ensuring that the pushrod’s stroke (often called “brake stroke” or “free travel”) is always within the optimal range every time the brake is applied.

2. Why Is It Used? (Manual vs. Automatic)

Before automatic slack adjusters became standard, vehicles used manual slack adjusters.

- Drawbacks of Manual Slack Adjusters:

1. Reliance on Skill: Required a mechanic to manually turn an adjustment screw based on experience and feel, making precision difficult to guarantee.

2. Uneven Adjustment:Easily led to inconsistent brake clearance between the left and right wheels of the vehicle, causing brake pulling (vehicle veering to one side during braking) and uneven tire wear (“scalloped” tires).

3. Safety Risks:Excessive clearance caused delayed braking and longer stopping distances. Insufficient clearance could lead to brake drag, overheating, and premature failure.

4. Time-Consuming and Labor-Intensive: Required frequent inspection and adjustment, increasing maintenance costs and vehicle downtime.

- Advantages of Automatic Slack Adjusters:

1. Maintains Optimal Clearance Automatically:No manual intervention needed; it constantly keeps the brake clearance at the designed optimum value.

2. Safety and Reliability:Ensures prompt and powerful brake response, shortens stopping distances, and enhances overall safety.

3. Economical and Efficient: Balanced braking leads to more even wear on tires and brake linings, extending their service life and reducing operating costs.

4. Low Maintenance and Convenience: Essentially maintenance-free, reducing vehicle downtime and labor costs.

3. How Does It Work? (Core Principle)

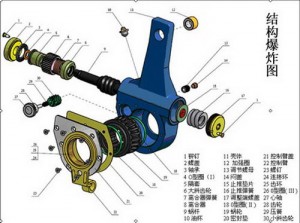

Its interior contains an ingenious one-way clutch mechanism(usually a worm and gear assembly).

1. Sensing Clearance ![]() uring each brake release cycle, the internal mechanism of the ASA senses the return travel distance of the pushrod.

uring each brake release cycle, the internal mechanism of the ASA senses the return travel distance of the pushrod.

2. Judging Wear: If the brake linings are worn, the clearance is larger, and the pushrod’s return travel will exceed a preset standard value.

3. Executing Adjustment: Once excessive return travel is detected, the one-way clutch engages. This action turns the worm gear by a tiny amount, effectively “taking up the slack” and advancing the camshaft’s starting position by a minuscule angle.

4. One-Way Action:This adjustment only occurs during brake release. When the brakes are applied, the clutch disengages, preventing the adjustment mechanism from being damaged by the immense braking force.

This process repeats continuously, achieving “incremental, reverse, automatic” compensation and ensuring consistent braking performance.

4. Key Considerations and Best Practices

1. Correct Installation and Initialization:

- This is the most crucial step! After installing a new automatic slack adjuster, you must manually set it to the “standard initial position.” The standard method is: turn the adjustment screw clockwise until it stops (indicating the shoes are fully contacting the drum), and then **back it off a specified number of turns or clicks** (e.g., “back off 24 clicks”). An incorrect back-off amount will either cause brake drag or render the automatic adjustment function useless.

2. Regular Inspection:

- Although called “automatic,” it is not entirely maintenance-free. The pushrod stroke should be measured regularly with a ruler to ensure it remains within the manufacturer’s specified range. A sudden increase in stroke length indicates that the ASA itself may be faulty or another brake system issue exists (e.g., a seized camshaft).

3. Replace in Pairs:

- To ensure balanced braking force across an axle, it is highly recommended to replace slack adjusters on both ends of the same axle in pairs, using identical brand and model products.

4. Quality is Paramount:

- Inferior quality slack adjusters may use poor materials, have substandard heat treatment, or low machining precision. Their internal clutch mechanisms can slip, wear out, or even break under heavy loads and frequent braking. This leads to “pseudo-automatic” adjustment or complete failure, instantly compromising the vehicle’s safety.

Summary

The slack adjuster is a classic example of a “small component with a massive impact.” Through ingenious mechanical design, it automates a process that required manual maintenance, significantly enhancing the active safety and economy of commercial vehicles. For owners and drivers, understanding its importance and ensuring its correct use and maintenance is a fundamental aspect of guaranteeing road safety.

Post time: Aug-20-2025